Inventory management

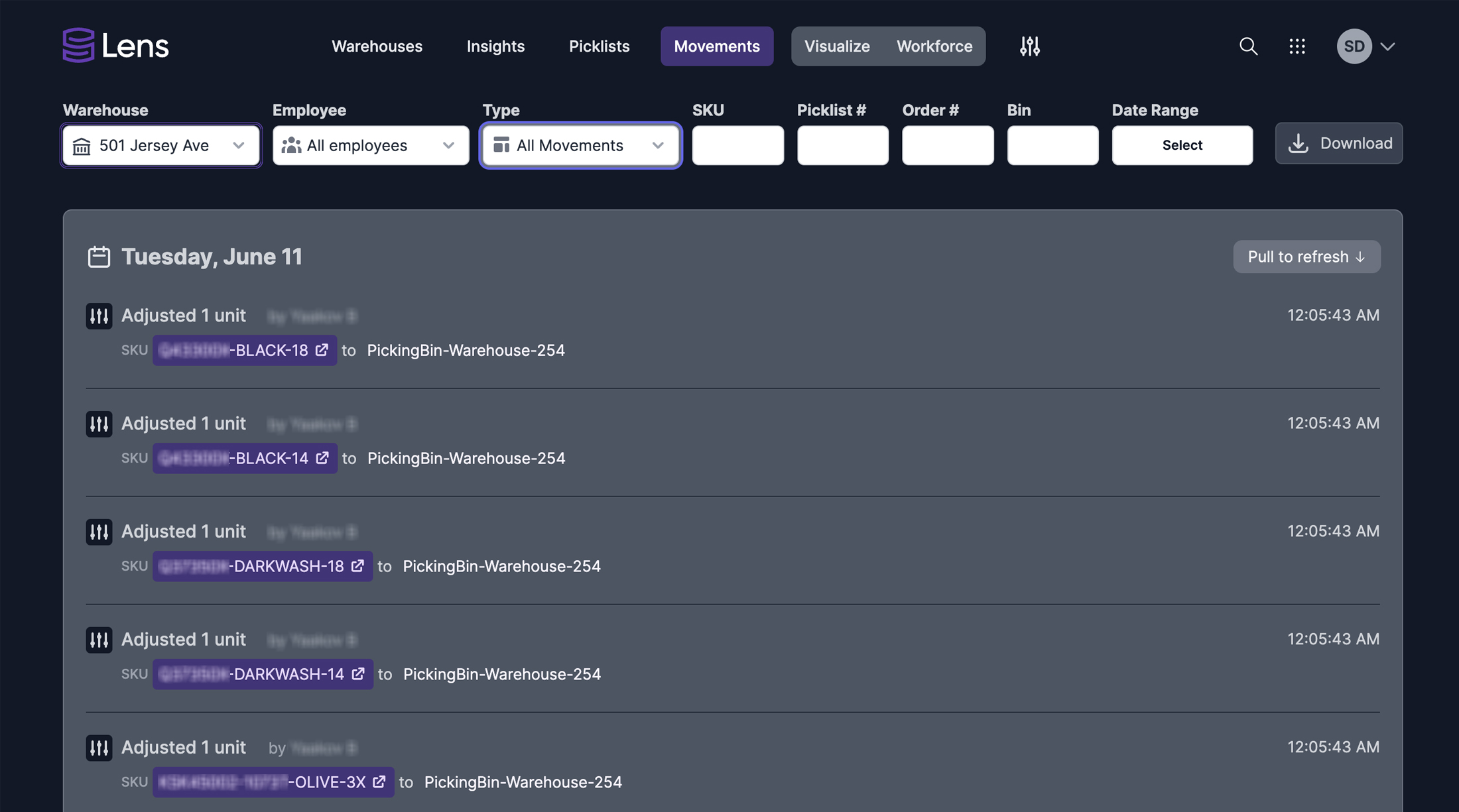

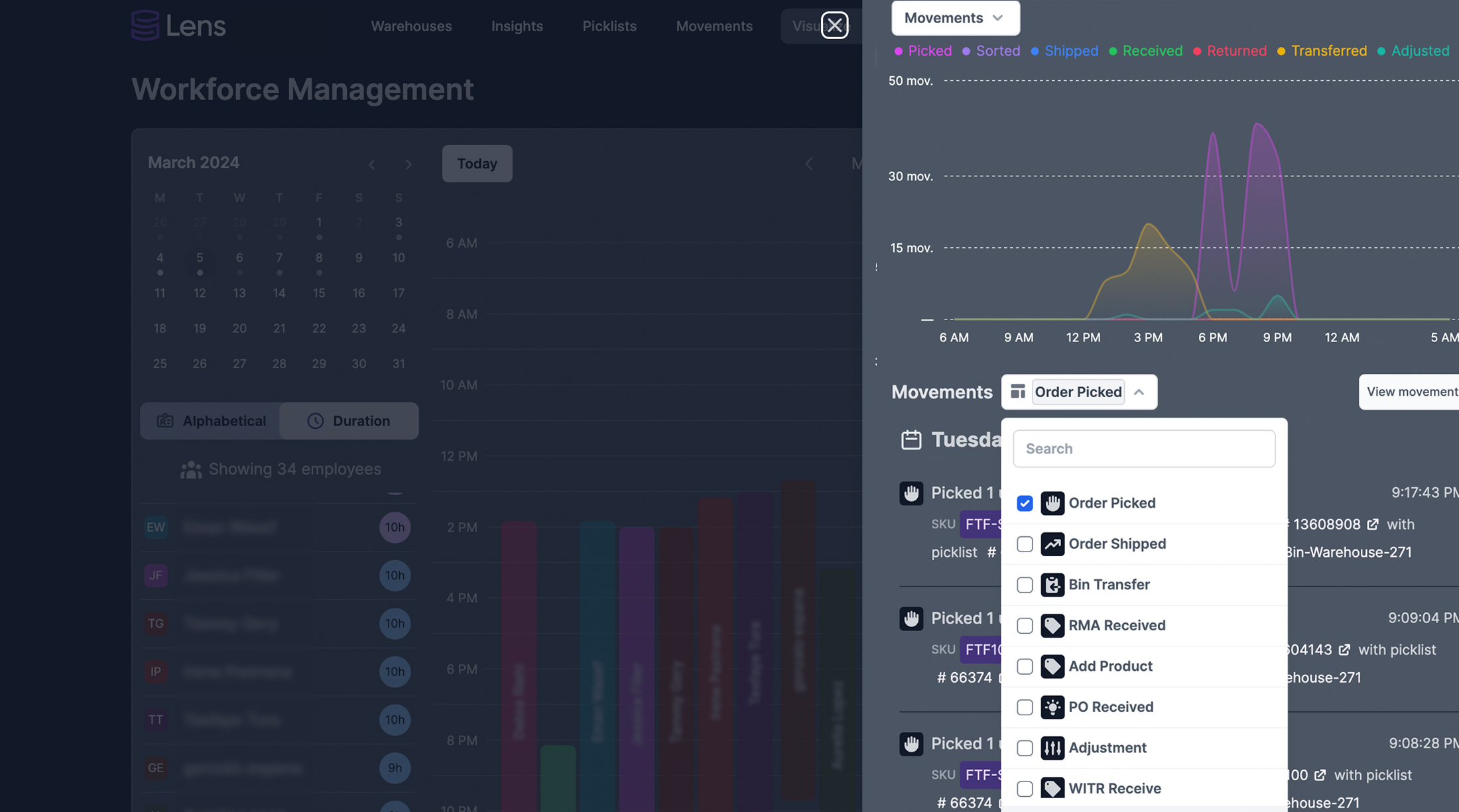

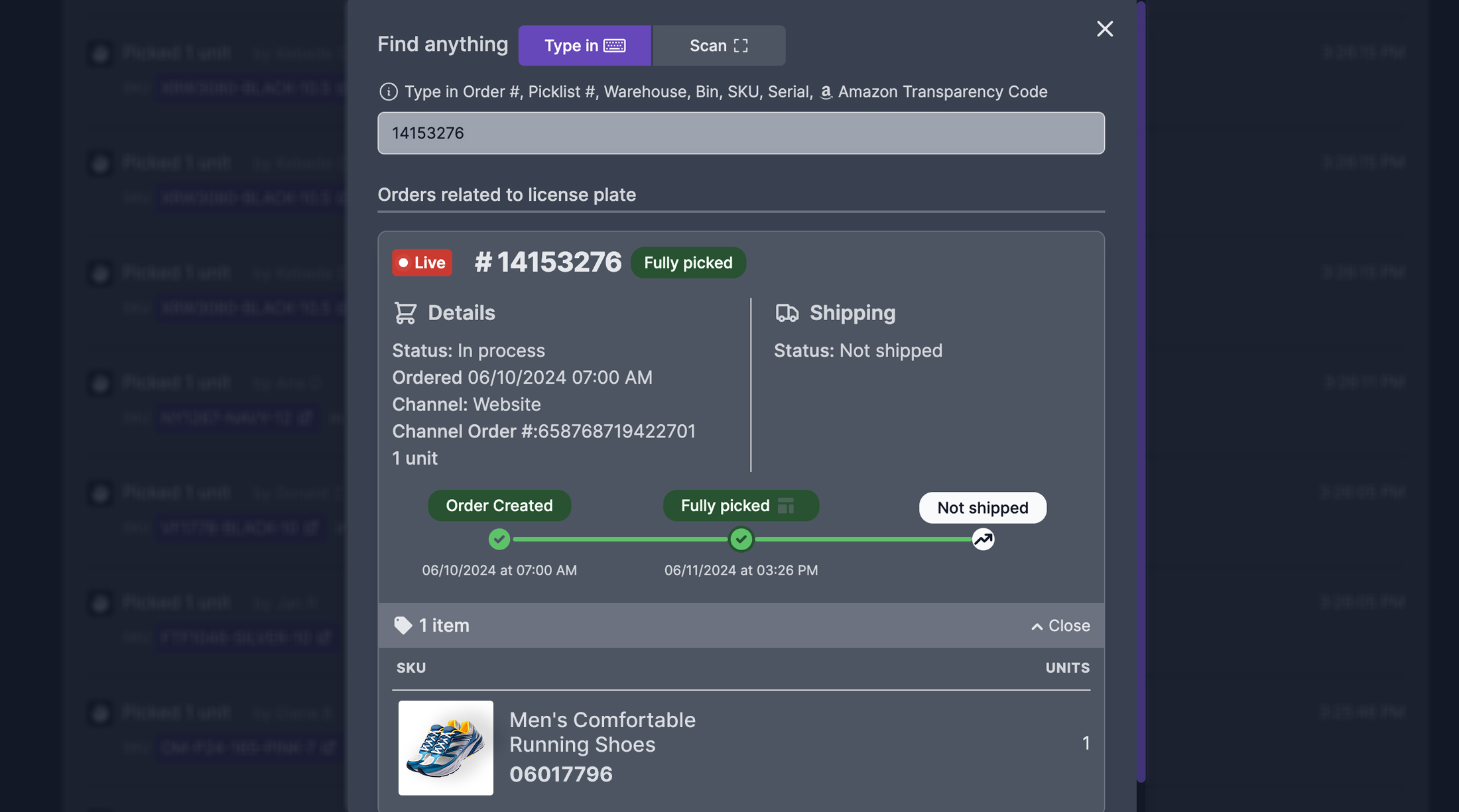

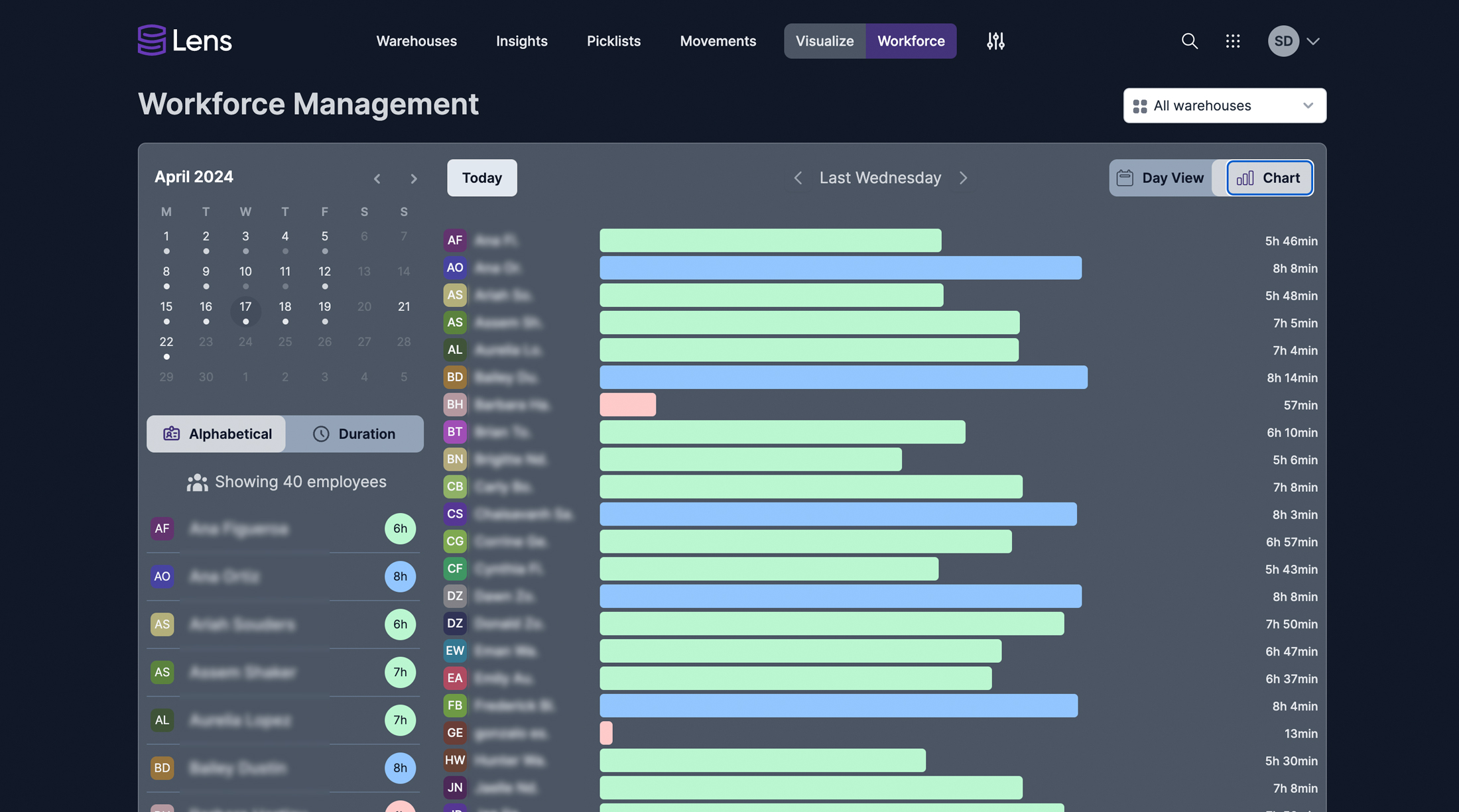

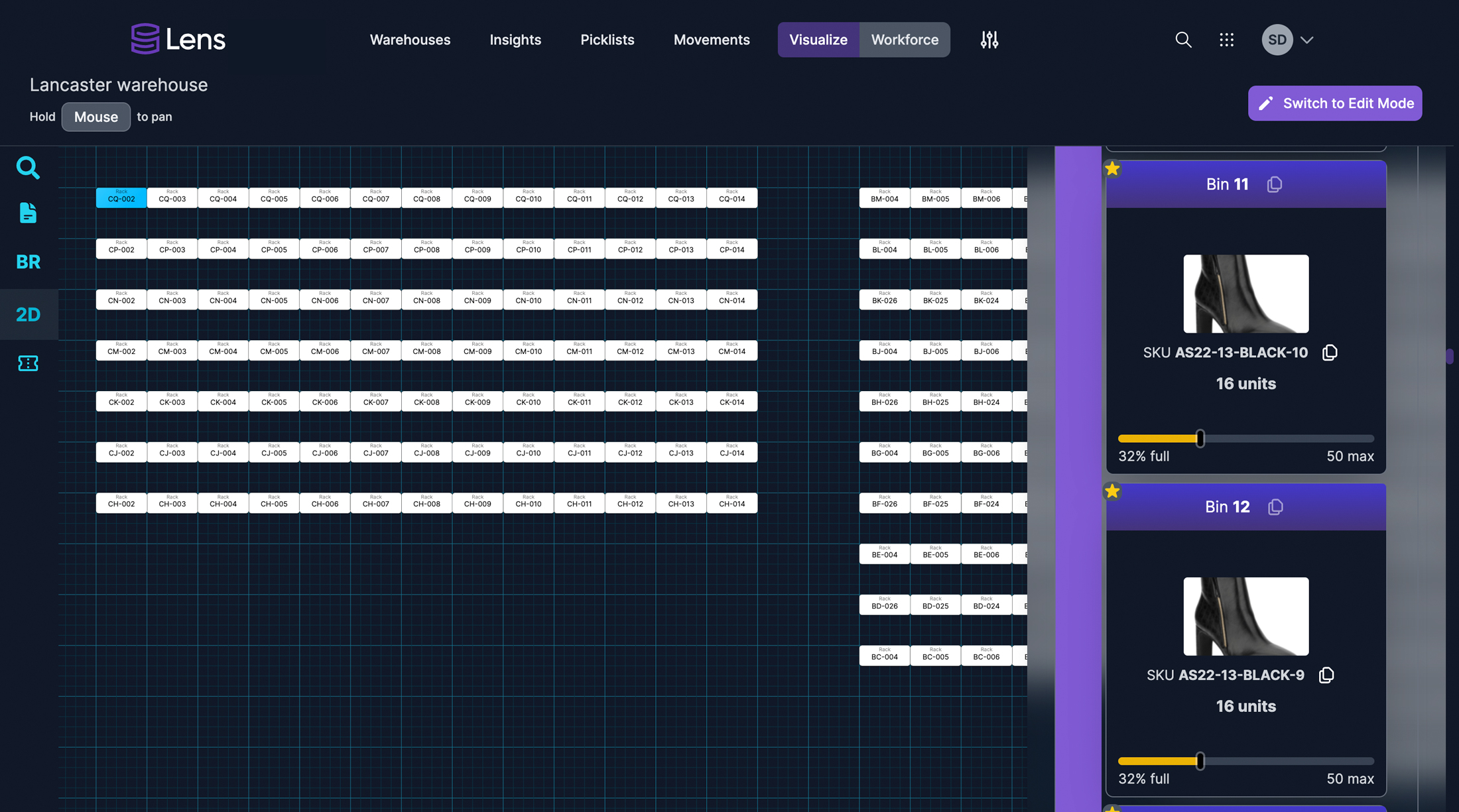

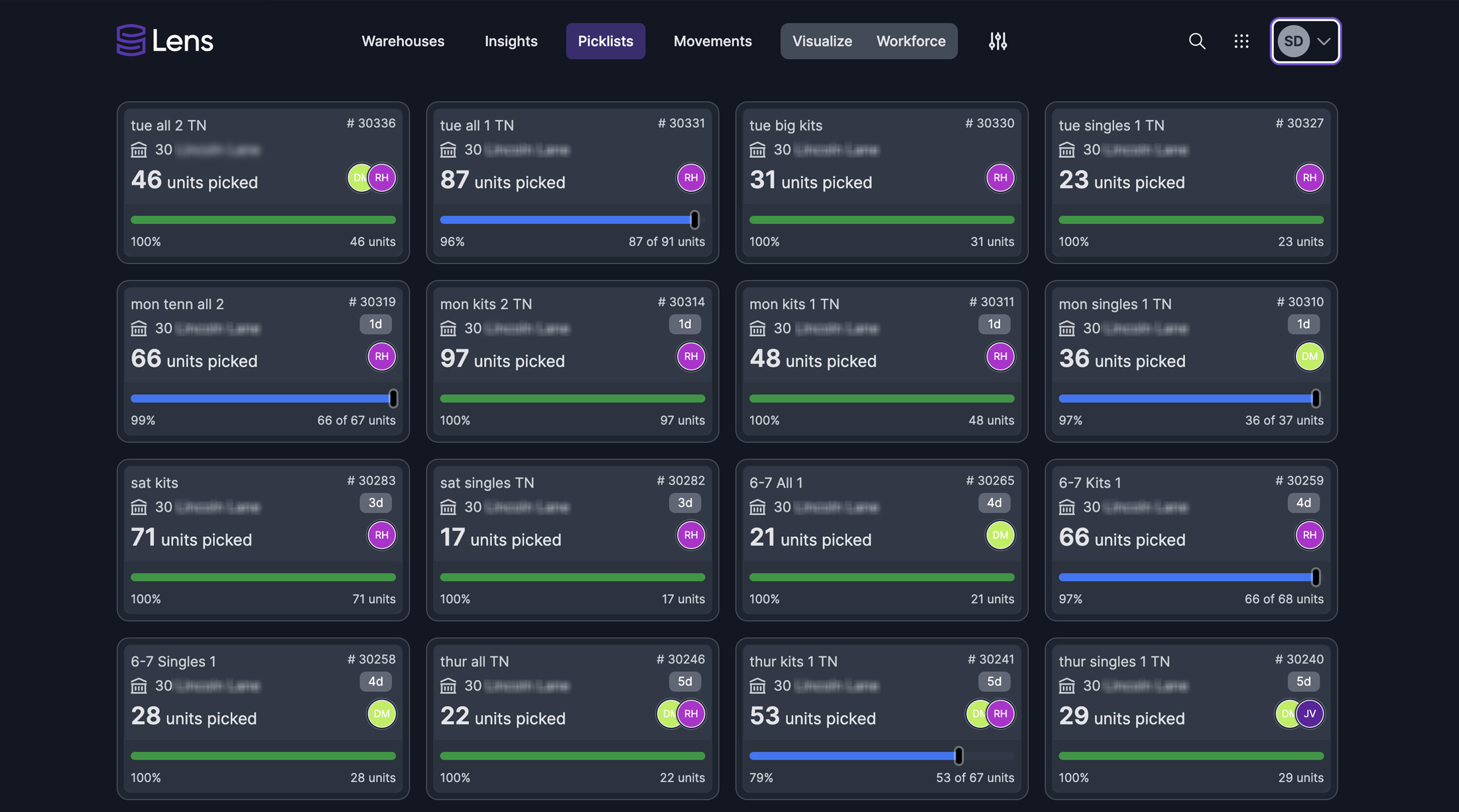

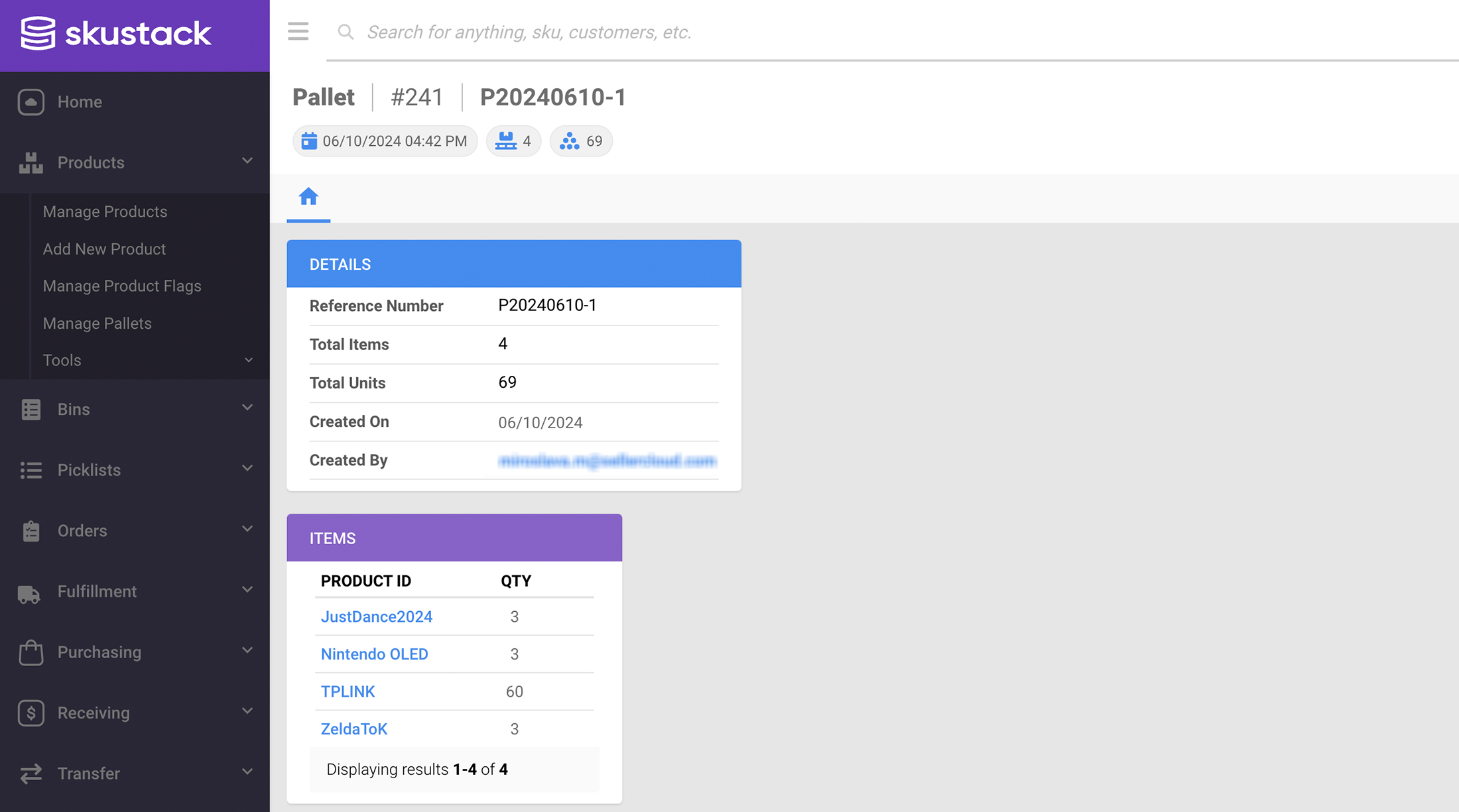

Real time tracking of inventory quantities and locations

Bin cycle counts

- Track in-and-out bin movements

- Generate bin cycle count reports based on bin traffic

- Make inventory adjustments on the bin level

- Maintain accurate inventory without putting your business on hold

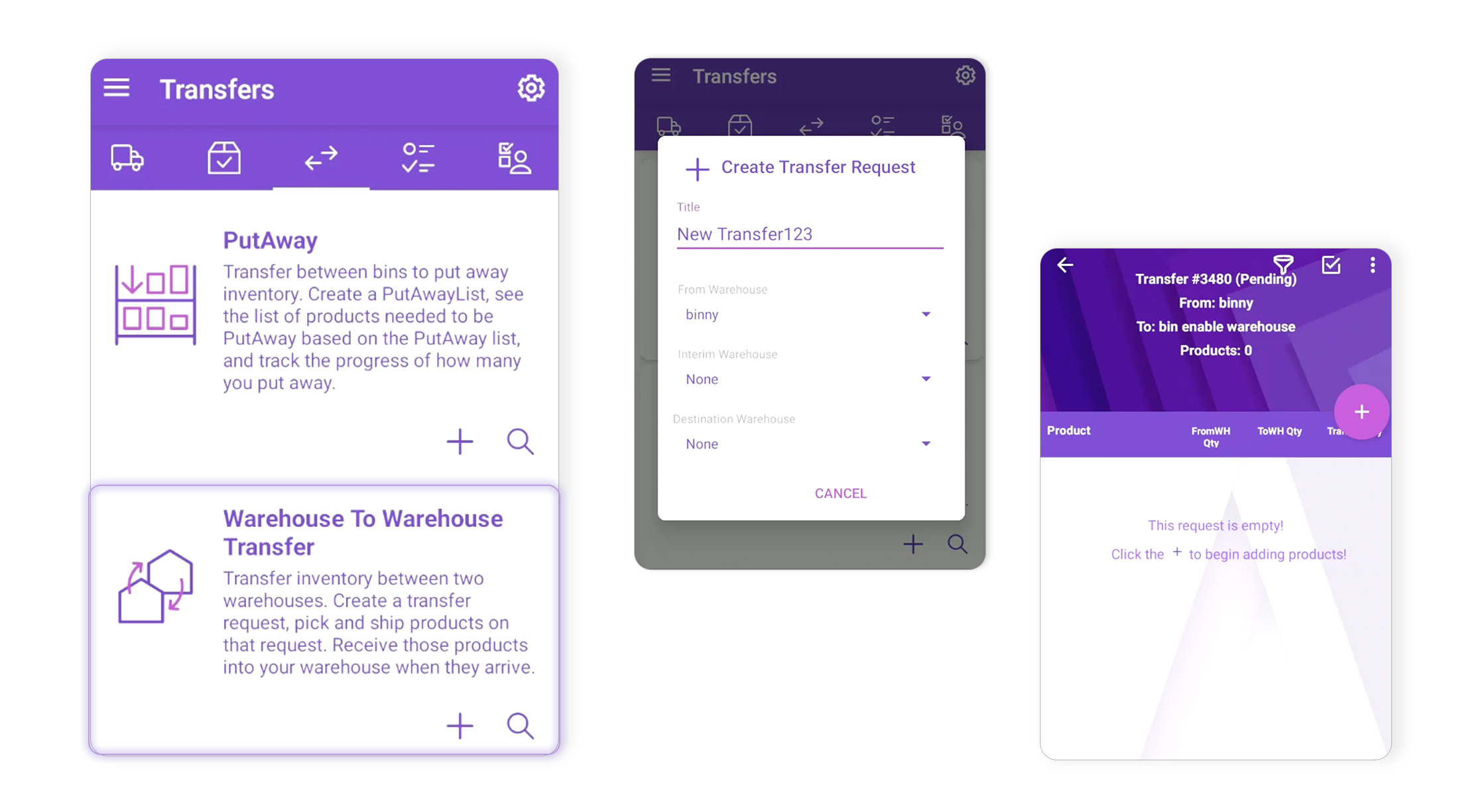

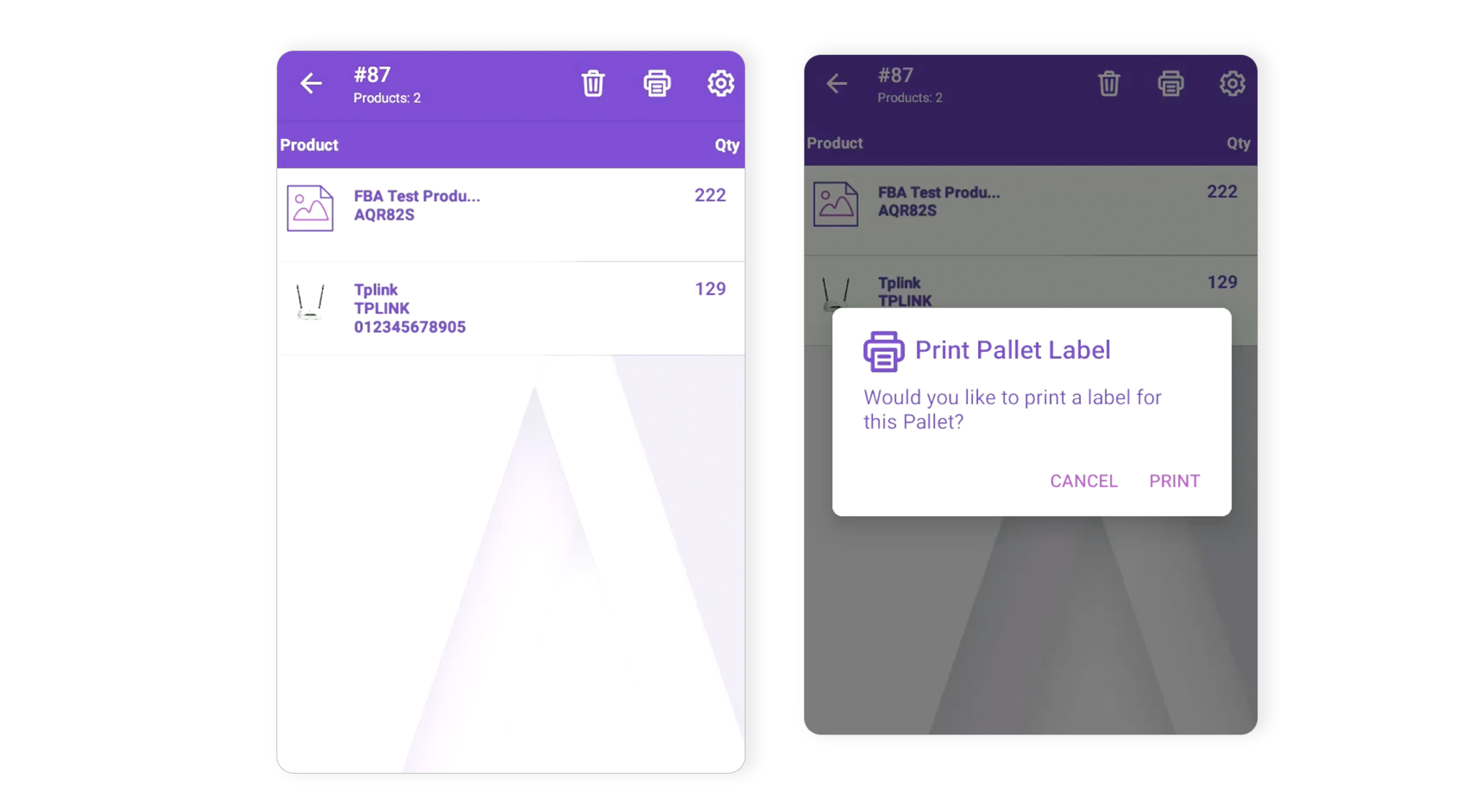

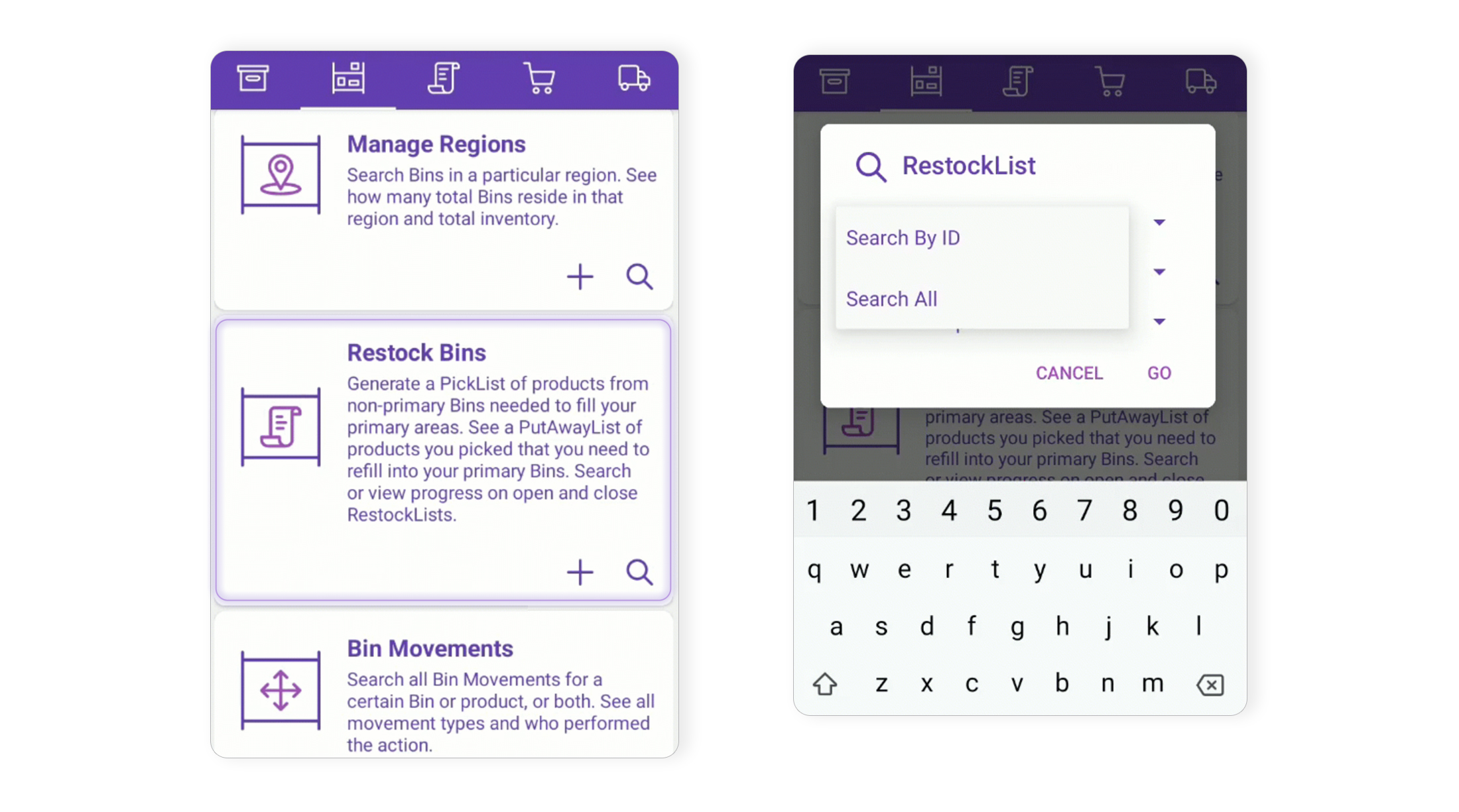

Replenishment

- Set low stock limits for bins

- Generate bin restocking lists

- Move inventory from overstock bins to picking bins

- Keep primary bins stocked to ensure picking efficiency

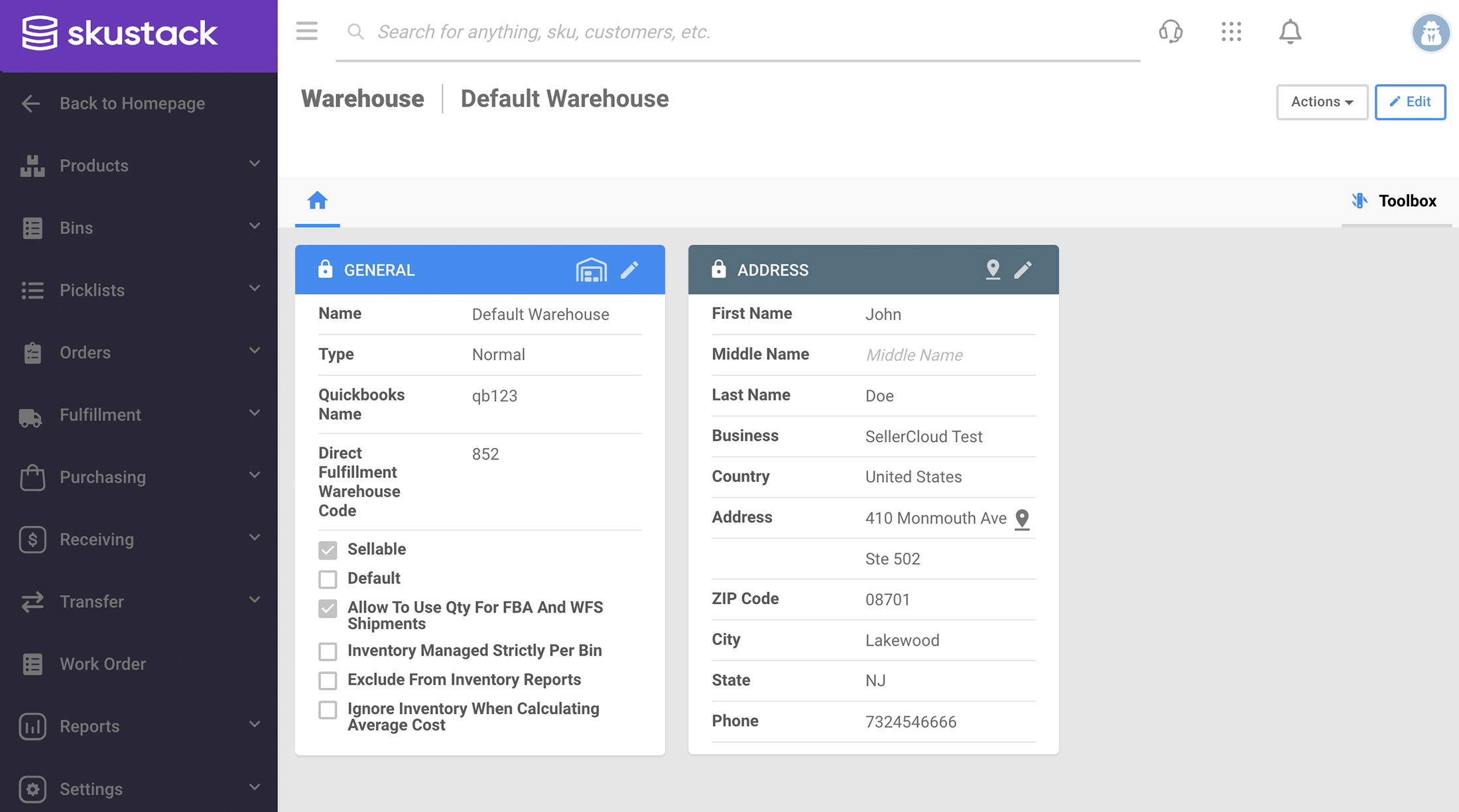

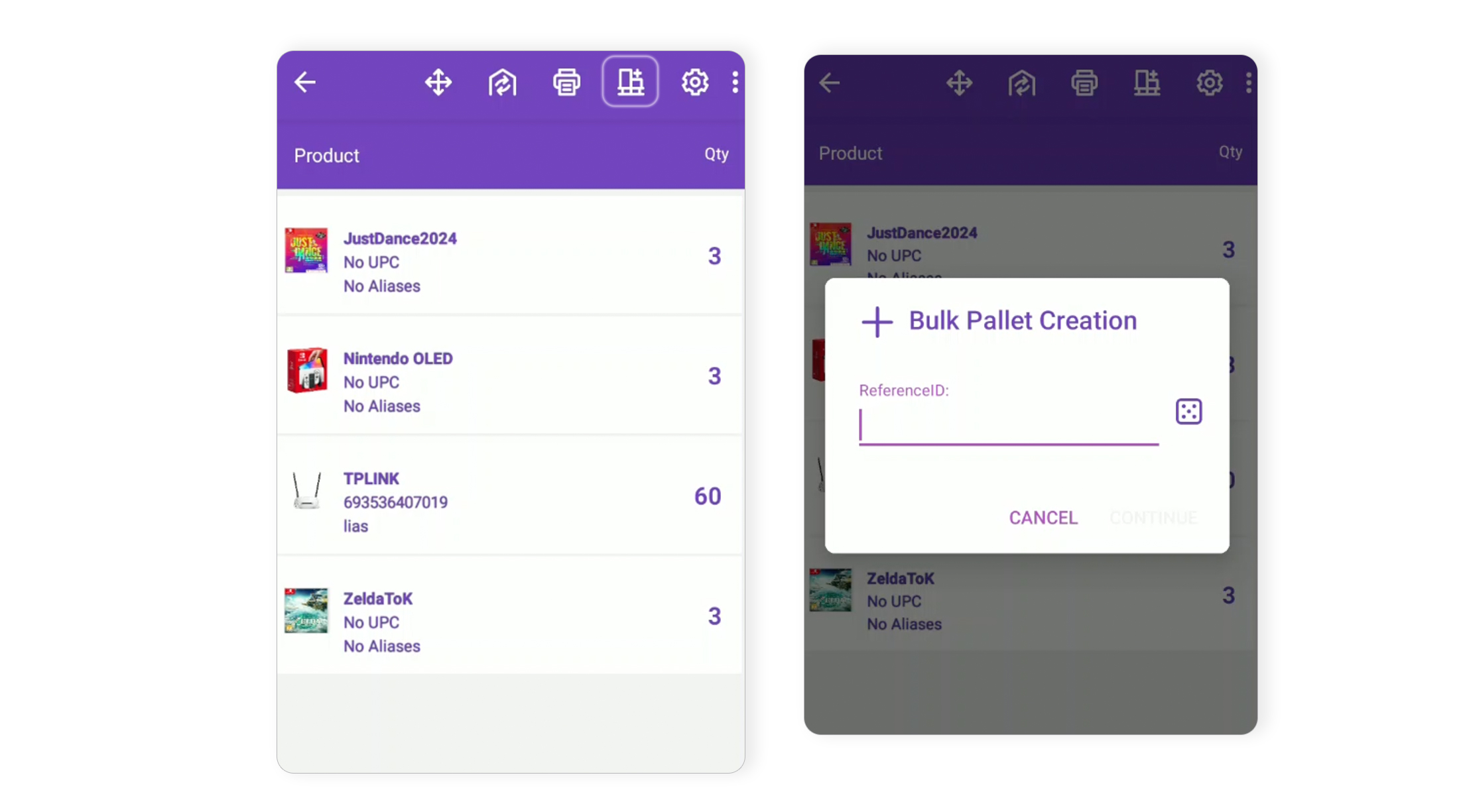

Manage regions and bins

- Build and assign products to bin locations

- Track inventory and make adjustments on a bin level

- Create regions to consolidate bin locations

- Manage regions and bins

- Perform bin cycle counts and manage replenishment

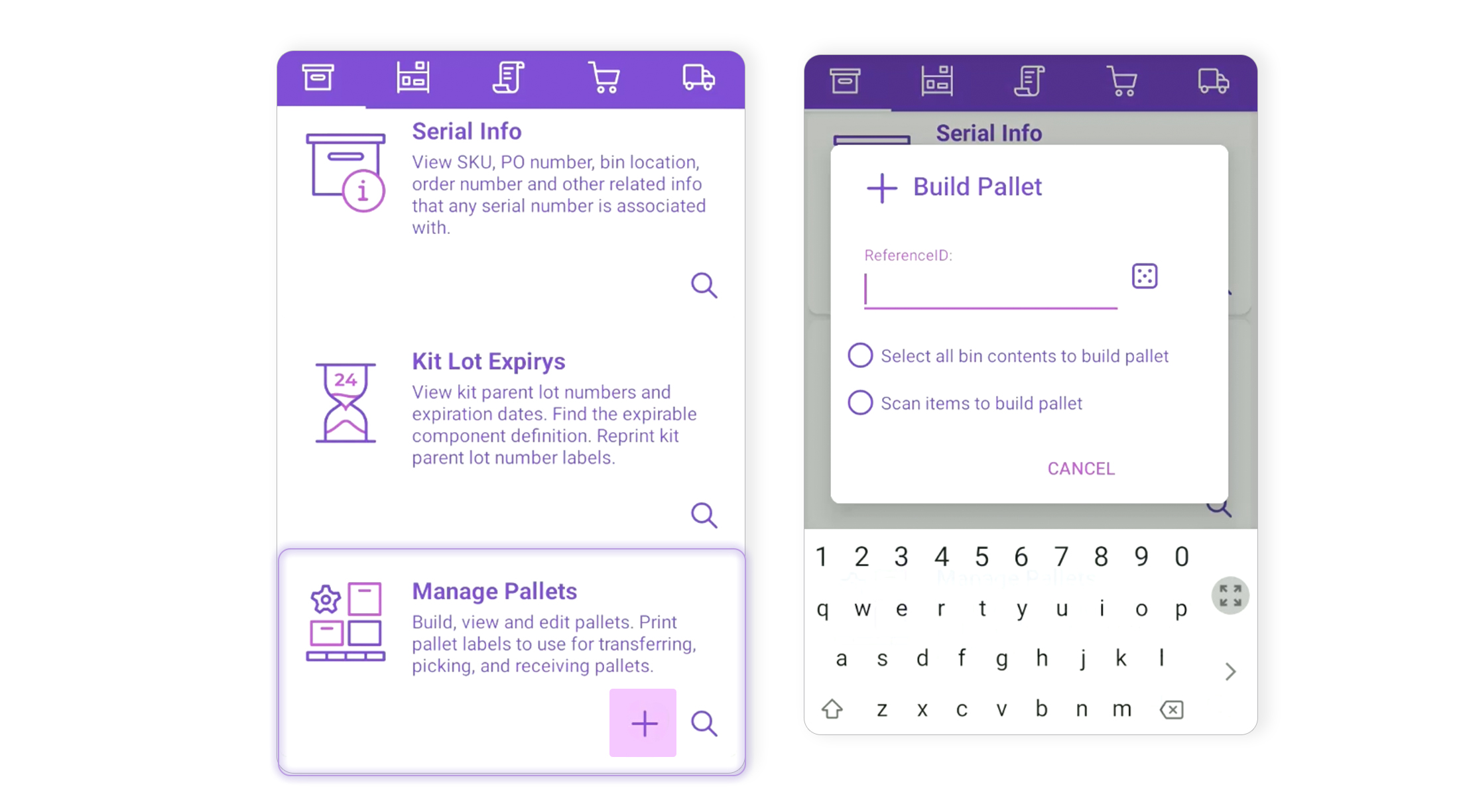

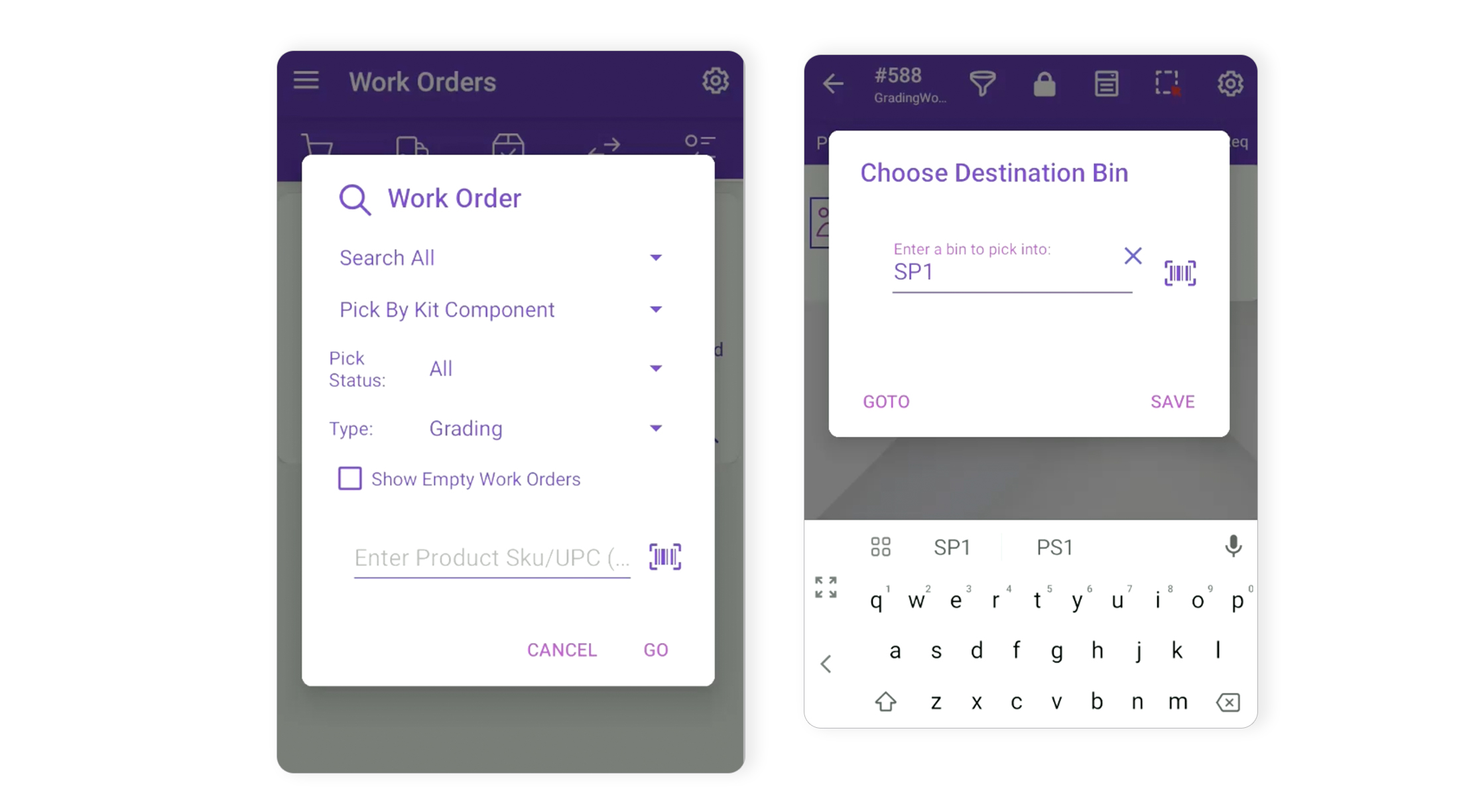

Serial number tracking

- Scan, save, and track serial numbers on a bin level

- Transfer serial numbers between SKUs during grading and repairing

- View the full warehouse lifecycle history of a serial number

- Protect against fraud with serial verification on RMAs

Lot expiration tracking

- Create lot numbers and labels for perishable products

- Track lot numbers for products on a bin level

- View and manage product lot numbers in a consolidated report

- Create inventory pulls to dispose of expired goods